Improved productivity- Automated robotic palletizing and industrial automation technology can improve productivity by decreasing the time and effort required to perform manual tasks, which allows for increased production and speedier processing times.Improved accuracy- Automated machines can improve accuracy and reduce the chance of errors as compared to manual processes leading to better product quality and uniformity.

Lower costs- Automation technology may reduce labor costs, equipment maintenance, as well as energy consumption.

Increased safety- Automated system can reduce the chance of injuries at work by eliminating manual handling tasks, and increasing the use and safety features such sensors and bars to protect yourself.

Better use of space: Automated storage systems and high-volume production facilities make the most efficient use of the available space, which allows for more efficient storage and utilization of materials and products.

There are a few things to consider when optimizing manufacturing efficiency using these techniques:

Upfront costs- Implementing automated technology can be costly and requires a substantial upfront investment.

Repair and maintenance- The cost of automated systems can increase due to their routine maintenance.

Training- It is possible that employees need to be taught how to use and maintain the automated system. This can be expensive and time-consuming.

Integration with existing programs- Automated software could require integration with systems already in place.

Technical expertise- Automated technology typically require a high degree of technical expertise to design installation, maintain, and test it, which is often difficult to identify and maintain.

In conclusion, maximizing production efficiency using automated robotic palletizing, industrial automation long-term storage, as well as high-volume production facilities can offer many benefits, but it's crucial to consider the cost, technological requirements, as well as the effects on employees and processes before implementing these technologies. Read the top Quick change over for site advice.

What Are Sealing, Packaging, Labeling, Coding, Coding, And Granular Filling Machines?

Filling Machines- Filling machines is used to fill containers that contain a particular product such as liquids or powders. These machines can improve the efficiency of the packing process as well as ensure that the right product is put in each container. This helps protect the product and keep its quality intact while it is being stored or transported.

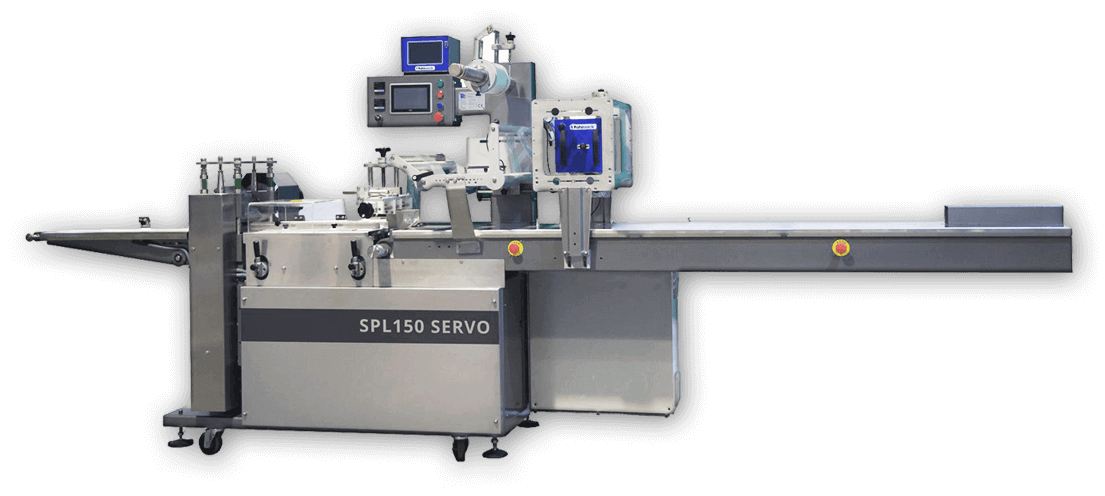

Wrapping Machine- Machine that wraps an item, or group of items, in a protective material (such as paper or plastic) to safeguard them during transport or storage. This can also be employed to keep your products tidy and neat.

Labeling Machine Labeling Machine- A labeling machine is the machine that is used to apply labels to the containers or items. It is possible to add information about the product on labels, such as nutrition information, ingredients and product descriptions.

Coding Machines- A computer that code a product container using a code such as a number, date or lot number. This is often used to track products and ensure that they are correctly handled and stored.

Liquid Filling Machine Liquid Filling Machine is a kind of filling machine that is specifically made to fill up containers with liquids. These machines are used in the chemical, pharmaceutical, and food industries.

Powder Filling Machine- This machine is specifically designed to fill powdered containers. They are commonly used in the chemical, pharmaceutical as well as food and beverage industries.

Granular Filling Machines are designed to fill containers filled with Granules. They are used extensively in the chemical, food and pharmaceutical industries.

The use of these machines for packaging can improve the effectiveness and quality of the packaging process. This will help to reduce costs, enhance the quality of the product and boost customer satisfaction. They can help protect products from damage during transportation and storage. Check out the recommended Automatic loading for more advice.

Packaging Solutions For Beverage, Food And Pharmaceutical Companies

Packaging solutions for food businesses They include flow fillers and vacuum packaging machines and thermoform fill sealers. These machines can help protect food products and extend their shelf-life. They also improve the efficiency and effectiveness of the packaging process. Packaging Solutions for Cosmetics Businesses The category covers liquid filling machines and labels machines. These machines can increase the efficiency of packaging processes' accuracy and ensure that each container contains the correct product.

Packaging Solutions for Industrial Companies. The solutions can include wrapping machines, palletizing machines and case erectors. These machines are used to arrange and protect the product, and increase effectiveness during packaging. They also ensure product storage and transport.

Packaging solutions for the beverage industry Beverage industries usually use filling machines and labels machines. Shrink wrapping machines are also used. These machines boost efficiency of the packaging process and ensure that every container contains the proper amount. Certain beverage companies employ aseptic packaging to increase the shelf life of their products.

Solutions for packaging household products The companies that sell household items utilize a range of packaging equipment, such as shrink wrapping machines, labeling equipment and the blister packaging equipment. These machines are used to improve the efficiency of packaging processes, and also ensure that the correct product is placed inside each container.

Packaging Solutions for Pharmaceutical Industry. The pharmaceutical industry uses many different packaging methods, such as blister packaging machines, liquid filling machines and a labeling machine. These machines are used to improve the precision of the packaging process and to ensure that the correct amount of product is placed in every container. The pharmaceutical industry frequently utilizes cleanroom packaging, which ensures the purity and quality of the products. See the top Adhesive tape for blog advice.

Benefits And Distinctions In Side-Load Versus Top-Load Cases And Tray Packing Machines

Top-load, side-load and top-load tray packing machines pack products in containers for transportation and storage. The main difference between them is how the product is loaded into the machine. This design allows for better access and improved ergonomics. Additionally, it makes quality control easier.

Top-load cartons and tray packing machine. The machine is small and space-saving and provides greater protection for the product. It also facilitates better use of space and decreases floor space. The product requirements, production process and space limitations of the factory will determine which machine to pick between side-load or top-load. The size and shape factors to be considered include the dimensions of the machine, quantity and speed of production, operator access ergonomics, and ergonomics.

Side Loading is a great option:

Operators have easy access

Improved ergonomics for operators

Improved visibility to ensure quality control

Top Load is a great product with many benefits

Space-saving design

Product protection has been improved

Better use of floor space.

Ultimately, the choice between top load and side load is contingent on the particular requirements of the product, the manufacturing process, as well as the space constraints of the facility. Have a look at the most popular Cooling for site recommendations.

What Are Other Packaging Machines Used To Package Items?

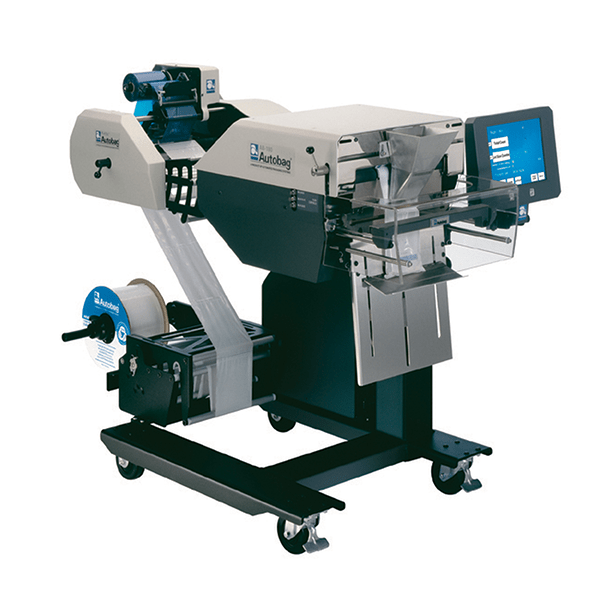

ARP monoblocks are high-speed packaging equipment that is able to automatically create blister packs. They are employed in the packaging of consumer products, medical devices and food. The ARP monoblock machine integrates various essential aspects of packaging in a compact device, such as filling with seals, sealing, as well as cutting.Blister Packaging Machines- Blister packing machines such as ARP monoblock machines, are designed to package items in blister packs that provide a clear view of the product and provide superior protection.

Carded Packaging machines- Carded packaging machines are designed for packaging products on a card backing. This ensures stability and support while transporting and storing.

Automated Cartoning Machines machines pack products in boxes and offer additional security. They also allow for branding and marketing information on the packaging.

Baumer machinery- Baumer is a prominent manufacturer of packaging equipment.

Cardboard box filling with case Erectors- They are used to make cardboard boxes out of folded, flat sheets. The boxes are then used to store products.

Semi-Automatic Case Erectors for Conveyor Processing. Semi-automatic cases erectors can be utilized for conveyor processing systems and are cost-effective ways to make cardboard boxes.

Automated Case Erectors that incorporate Robotic Arm Technology- Automatic case Erectors using robotic arms are a completely automated method of making of cardboard boxes, offering more effectiveness and flexibility.

Clamshell Machines for Packaging Materials Clamshell machines can create an enveloping clamshell. This offers excellent protection and permits clear view of the item.

Filling Machines for Food and Beverage Packaging Filling machines are used to fill packages with pastes, liquids and other types of food and beverage products.

Auger/Agitator Filler to fill Dry Mix Packaging. Auger or agitator liners are utilized to fill dry mix packaging using powders or granules.

Flow Fillers For Liquids and Edible Packaging The Flowfillers are utilized to fill containers with liquids. They they also permit precise control of fill quantity.

Positive Displacement Pill Filler for Gel Lotion, Cream, and Cream Packaging. These fillers are designed to be filled with strong products like lotions or gels.

Tablet Fillers for Portion-Counted Product Packaging Tablet fillers are employed to pack products with a portion count, like tablets and pills.

Vertical Form Fill Sealing Machine A vertical form fill sealing machine is an type of packaging machine that creates a pouch or bag out of the roll of flexible packaging material, fills the pouch with the product and seals it in a package. View the top rated Engineers for blog info.